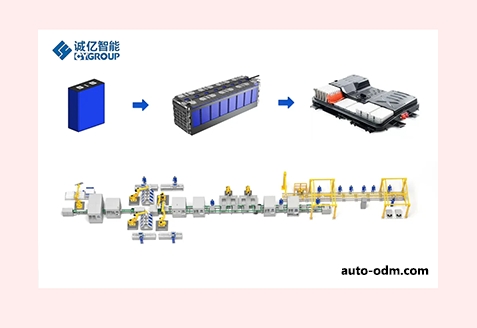

Shenzhen - Aug 21, 2025 - Comwin Group, a global provider of automotive original design manufacturing (ODM) solutions, today announced the launch of its modular battery pack assembly line designed to accelerate energy-storage battery manufacturing, enhance quality control, and reduce total cost of ownership for energy-storage battery producers.

The modular line combines scalable automation, standardized modules, and integrated quality checks to support multiple energy-storage battery chemistries and pack configurations (such as NMC and LFP), and is designed to minimize changeover time, boost output, and maintain consistent performance across high-volume production.

The modular design enables customers to scale output by adding or reconfiguring line modules without major downtime, from about 10,000 to 50,000 packs per year. Automated material handling, robot-assisted assembly, and inline inspection reduce manual handling and help operators ensure tight tolerances. The system also integrates with existing plant data platforms to provide real-time analytics and traceability for each pack.

“We designed this line to deliver speed, reliability and flexibility to energy-storage battery manufacturing,” said Liu Wei, chief executive officer of Comwin Group. “By combining modularity with intelligent quality controls, manufacturers can shorten ramp-up times and maintain consistency across shifts.”

“Digital twin simulations and predictive maintenance capabilities help plants plan downtime and optimize maintenance schedules,” added Maria Rodriguez, chief technology officer of Comwin Group. “This approach lowers total cost of ownership over the life of the line.”

Industry analysts say scalable, automation-enabled battery-pack lines are increasingly essential as demand for energy-storage systems grows and OEMs seek to reduce production bottlenecks. Comwin Group says the modular line is designed to adapt to evolving chemistries and form factors, enabling manufacturers to stay ahead of shifting market requirements.

The modular line is available to order worldwide, with options for on-site installation, remote monitoring, and full after-sales support. Comwin Group will showcase the line at upcoming industry events and will offer pilot deployments to select customers.

Comwin Group is a global provider of end-to-end automotive original design manufacturing (ODM) solutions, specializing in EV battery-pack assemble line, energy storage battery assemble line, prismatic battery pack assemble line, and comprehensive production-line automation. The company serves automakers, Tier-1 suppliers, and contract manufacturers across Asia, Europe, and North America, with the capability to extend to energy-storage applications as needed.

Media Contact

Company Name: Shenzhen Comwin Intelligent Equipment Group Co., Ltd.

Contact Person: Key Shaw

Email: Send Email

Phone: 15015614961

City: Shenzhen Baoan

State: Guangdong

Country: China

Website: https://auto-odm.com/battery-pack-assembly-line-manufacturer/energy-storage-power-module-pack-production-line/